C45 Block For Plastic Steel Mould

C45 Block For Plastic Steel Mould Specification

- Material

- C45

- Finish

- Bright

- Capacity

- 5000 Kg

- Specific Use

- For construction

- Shape

- Rectangular

- Material Grade

- C45 /EN8

- Length

- 4mtr Meter (m)

- Pipe Type

- Plate

- Grade

- C45

- Usage

- New

- Type

- Block bar

C45 Block For Plastic Steel Mould Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Mill T.C./ Lab T.C./ Ultrasonic Reports

About C45 Block For Plastic Steel Mould

About Our Company Leveraging on our vast Industrial Experience We Bhagwati Enterprise, are acknowledged as one of the leading Supplier, Exporter, Trader, Importer & Wholesaler/Distributor of the Industry. Since 1992 we are dealing in a broad assortment of Alloy Steel, Tool Steel, Die Steel, Steel Bars, Carbon Steel Round Bars, SAE 8620 Steel Round Bars, EN Series Steel Round Bars, , AISI Series Steel Round Bars, Flat Bars, Free Cutting Steel, Steel Plates & Nitriding Steel. House Of MS Seamless Pipe To maintain the flawless of the products our Vendors Employ Cutting edge technology and tools in the manufacturing process. After this, all these products

Plastic Mold Steel Suppliers in Vadodara Gujarat India.

-

Mold steel Suppliers In Vadodara

-

Mold steel manufacturers in India

-

Tool steel for plastic molds

-

precision mold steel

-

pre-hardened mold steel

-

hardened tool steel

-

hot work mold steel

-

Cold work tool steel

-

injection mold steel grade

-

high-performance mold steel

-

Plastic mould steel plate

- Hot rolled C45 plate

- Precision ground C45 plate

- Pre-machined C45 steel

- C45 die Steel Suppliers in Vadodara

- Die Steel Manufacturer In Gujrat

- Tool Steel Manufacturer In India

- Die Steel Supplier In Vadodara

- High-Speed Steel (HSS)

- Plastic Mould Steel

- Forged Die Steel

- C45 Block Leading Stockists & Suppliers In India.

- Dealers of C45 Steel Round Rods, Flat bars, Rectangular bars, Hex bars, Pipes, Plate.

| Thickness | 150 mm |

| Usage/Application | Industrial |

| Shape | Rectangular |

| Material Grade | C45 |

| Material | C45 Block |

| Size | 1500X6000 |

| Finish | New |

| Country of Origin | Made in India |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Bars Category

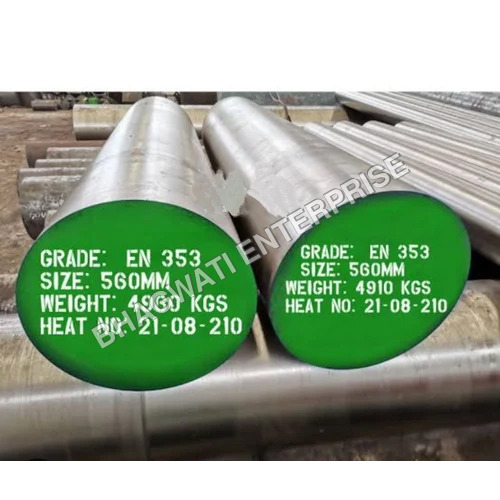

EN353 Case Hardening Steel Round Bar

Price 110 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Round bar

Finish : Polished

Material : EN353 Round

Specific Use : For construction

Aluminium Round Bar

Price 280 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Round bar

Finish : Polished

Material : Aluminium

Specific Use : For construction

EN Series Steel Bars

Price 70.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Round bar

Finish : Coated

Material : Alloy Steel

Specific Use : Plastic Die Unit

WPS Flat

Price 180 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Flat bar

Finish : New

Material : WPS Flats

Specific Use : For construction

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free