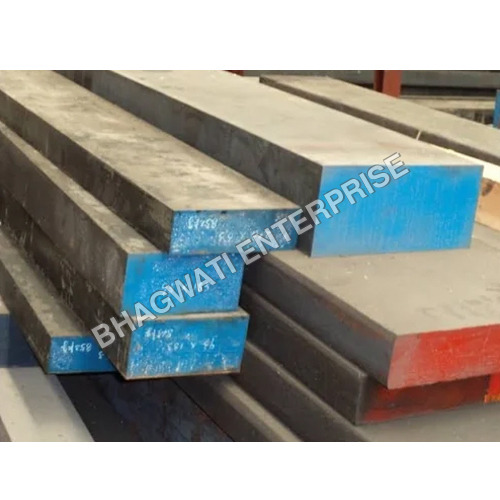

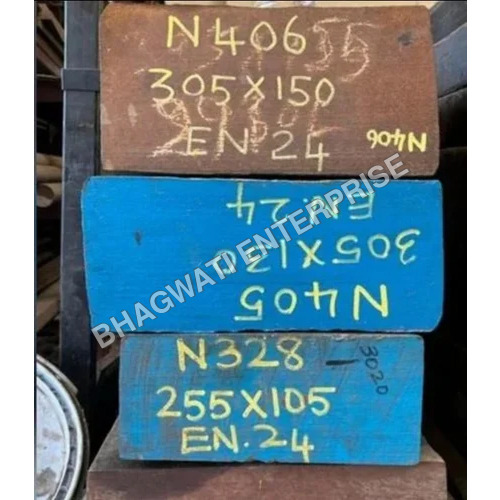

EN24 Alloy Steel Flats

EN24 Alloy Steel Flats Specification

- Product Name

- Other

- Steel Type

- Alloy Steel

- Steel Product Type

- Steel Bars

- Grade

- EN24

- Surface

- Polished

- Application

- Construction

EN24 Alloy Steel Flats Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 2-7 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Lab T.C.

About EN24 Alloy Steel Flats

About Our Company Leveraging on our vast Industrial Experience We Bhagwati Enterprise, are acknowledged as one of the leading Supplier, Exporter, Trader, Importer & Wholesaler/Distributor of the Industry. Since 1992 we are dealing in a broad assortment of Alloy Steel, Tool Steel, Die Steel, Steel Bars, Carbon Steel Round Bars, SAE 8620 Steel Round Bars, EN Series Steel Round Bars, , AISI Series Steel Round Bars, Flat Bars, Free Cutting Steel, Steel Plates & Nitriding Steel. House Of MS Seamless Pipe To maintain the flawless of the products our Vendors Employ Cutting edge technology and tools in the manufacturing process. After this, all these products.

EN24 flat bars are aheat-treatable alloy steel offering high strength, toughness, and good wear resistance.They are commonly used in applications requiring high strength and durability, such as axles, shafts, gears, and bolts.Here's a more detailed look at EN24 flat bars:1. Chemical Composition:

-

Sizes: (e.g., EN24 Flat Bars Sizes from 10mm x 20mm to 100mm x 300mm)

-

Forms: Cold Drawn / Hot Rolled / Forged / Peeled & Ground

-

Supply Condition: Supplied in Annealed / Hardened / Tempered Condition

-

EN24 Flat Bar Suppliers in Gujrat

-

EN24T Flat Bar Stockists in Vadodara

-

EN24 Alloy Steel Flat Bar

-

EN24 Forged Flat Bar

-

EN24 Annealed Flat Bar

-

EN24 Precision Ground Flat Bar

-

EN24 Steel Flats Suppliers in India

-

EN24T Hardened Flat Bar

- EN24 Flat Bar for Automotive Components

- EN24 Flat Bar for Aerospace Applications

- EN24 Flat Bar for Tooling & Dies

- EN24 Flat Bar for Power Transmission

- EN24 Steel for Heavy Engineering

- EN24 for Oil & Gas Applications

- EN24 Steel for Shafts and Gears

- EN24 Flat Stock for Manufacturing

-

The top EN24 Flat manufacturers are

-

The top EN24 Flat Suppliers in India.

- Dealers of EN24 Steel Flat bars, Rectangular bars, Square Bar.

| Length | 6 m |

| Thickness | 20 mm |

| Shape | Flat |

| Single Piece Lengh | 6 meter |

| Country of Origin | Made in India |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flat Bars Category

En8 C45 Flat Bar

Price 95 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface : Coated

Grade : En8

Steel Product Type : Steel Bars

Steel Type : Mild Steel

EN19 Alloy Steel Flat

Price 90 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface : Coated

Grade : SAE 8620

Steel Product Type : Steel Plates

Steel Type : Alloy Steel

En 24 Flat Bar

Price 110.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface : Polished

Grade : En 24

Steel Product Type : Steel Plates

Steel Type : Alloy Steel

Wps Flat For Plastic Mould Steel

Price 180.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface : Polished

Grade : WPS

Steel Product Type : Steel Bars

Steel Type : Tool Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free