C45 Carbon Steel Plate For Plastic Mould Industry

Product Details:

- Product Name Other

- Steel Type Carbon Steel

- Steel Product Type Steel Plates

- Grade C45

- Shape Plate

- Surface Coated

- Application Other

- Click to View more

C45 Carbon Steel Plate For Plastic Mould Industry Price And Quantity

- 80 INR/Kilograms

- 100 Kilograms

C45 Carbon Steel Plate For Plastic Mould Industry Product Specifications

- Other

- Other

- Steel Plates

- Plate

- C45

- Coated

- Carbon Steel

C45 Carbon Steel Plate For Plastic Mould Industry Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Loose

- Asia

- All India

- Mill T.C./ Lab T.C. / Ultrasonic Reports

Product Description

C45 Plate Plastic Mould Steel refers to a specific application of C45 steel, which is commonly used in the manufacture of plastic moulds. C45 steel, known for its medium carbon content and good mechanical properties, can be used in mould-making when certain modifications or treatments are applied to enhance its performance in this role. Here™s a detailed description:

C45 Plate Plastic Mould Steel Description

1. Material

- Composition C45 steel is a medium-carbon steel with approximately 0.45% carbon content. It also contains small amounts of manganese and other trace elements. This composition provides a balance of strength, hardness, and machinability.

- Properties While C45 steel is not inherently a mould steel, it is used in plastic mould applications due to its good strength and machinability. For mould applications, it may undergo additional processes to enhance its performance.

2. Manufacturing Process

- Production C45 plates are produced by hot rolling or cold rolling processes. These processes shape the steel into flat plates of various thicknesses.

- Heat Treatment To enhance its suitability for mould applications, C45 steel plates are often heat-treated through processes such as annealing, hardening, and tempering. Heat treatment improves hardness and wear resistance, crucial for mould performance.

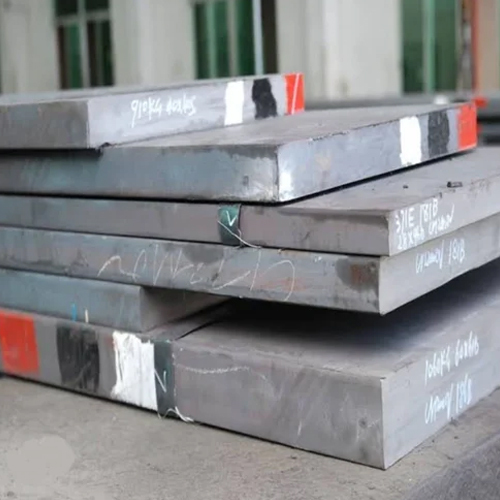

3. Shape and Dimensions

- Shape Flat, rectangular plates with uniform thickness.

- Thickness Available in a range of thicknesses, typically from a few millimeters to several centimeters, depending on the mould requirements.

- Dimensions Supplied in standard sizes, but custom dimensions can be provided. Common dimensions include lengths from 1 to 6 meters and widths from 0.5 to 3 meters.

4. Properties

- Strength Provides adequate tensile and yield strength for plastic mould applications. It is strong enough to withstand the pressures and stresses encountered during the moulding process.

- Hardness Medium hardness, which can be enhanced through heat treatment. Suitable for moulds that require a moderate degree of hardness and wear resistance.

- Machinability Good machinability allows for precise fabrication of complex mould shapes and features.

- Ductility Provides a reasonable level of ductility, which is important for maintaining mould integrity under operational conditions.

5. Applications

- Plastic Moulds Used for producing various plastic parts, including automotive components, consumer goods, and industrial products. C45 steel plates are used in the fabrication of moulds that shape plastic materials.

- Tooling Employed in tooling applications where moderate hardness and strength are required.

6. Finishes and Coatings

- Surface Finish Plates can have different finishes, such as hot-rolled or cold-rolled, depending on the production process and required surface quality.

- Coatings Moulds may be treated with coatings or surface treatments to improve their resistance to wear, corrosion, and plastic sticking.

7. Standards and Compliance

- Standards Manufactured according to relevant standards, such as those specified by ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). These standards ensure that the plates meet the required chemical composition and mechanical properties.

- Certification Quality certifications may be available to confirm compliance with industry standards and performance requirements.

8. Advantages

- Cost-Effective C45 steel is generally more affordable compared to high-alloy mould steels, making it a cost-effective choice for certain moulding applications.

- Versatility Provides a good balance of properties for various moulding applications, especially when enhanced through heat treatment.

- Customizability Available in various sizes and thicknesses to meet specific mould design and performance needs.

C45 Plate Plastic Mould Steel is used in the production of plastic moulds where medium carbon steel offers a suitable combination of strength, hardness, and machinability, particularly when enhanced through heat treatment processes.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free