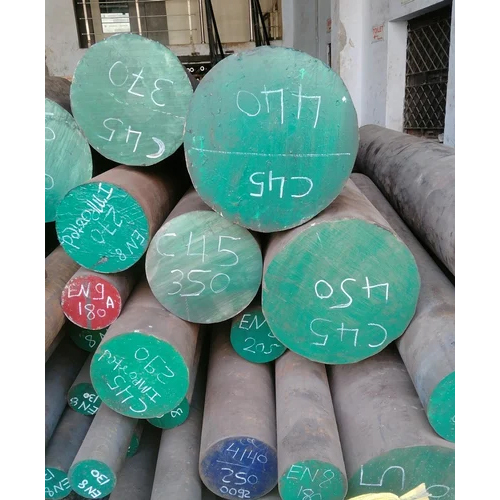

En Series Steel Bars

Product Details:

- Material Alloy Steel

- Type Round bar

- Specific Use Plastic Die Unit

- Length 6 Meter (m)

- Grade Alloy Steel

- Application Enginiring Unit

- Standard New

- Click to View more

En Series Steel Bars Price And Quantity

- 100 Kilograms

- 70 INR/Kilograms

En Series Steel Bars Product Specifications

- Coated

- New

- Enginiring Unit

- Alloy Steel

- Plastic Die Unit

- Round bar

- 6 Meter (m)

- Alloy Steel

En Series Steel Bars Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- 1 Days

- Sample costs shipping and taxes has to be paid by the buyer

- Loose/ Packing Bundle

- Asia

- All India

- Mill T.C./ Lab T.C. / Ultrasonic Reports

Product Description

EN Series Steel Round Bar refers to a category of round bars made from steel that meets specific European standards. These bars are used in a variety of industrial applications due to their strength, machinability, and versatility. Hereïs a detailed description:

EN Series Steel Round Bar Description

1. Material

- Composition EN Series steel round bars are made from carbon steel, alloy steel, or stainless steel, depending on the specific grade. The EN (European Norm) standards define the composition and properties of the steel used.

- Common Grades Includes various grades with different properties, such as:

- EN 1.0501 (C45) Medium-carbon steel with good strength and machinability.

- EN 1.4401 (316) Stainless steel with high corrosion resistance, suitable for harsh environments.

- EN 1.7225 (42CrMo4) Alloy steel with high strength and toughness.

2. Manufacturing Process

- Production Round bars are typically produced through processes such as hot rolling or cold drawing.

- Hot Rolling Involves heating the steel to a high temperature and then rolling it into bars. This process is used to produce bars with a larger diameter.

- Cold Drawing Involves reducing the diameter of the bars at room temperature, resulting in a more precise and smoother finish.

- Heat Treatment Bars may undergo heat treatment processes like annealing, quenching, or tempering to achieve desired mechanical properties.

3. Shape and Dimensions

- Shape Circular cross-section with a uniform diameter throughout the length.

- Diameter Available in a wide range of diameters, typically from a few millimeters to several inches.

- Length Supplied in standard lengths, which can vary but commonly include sizes from 3 to 6 meters (10 to 20 feet). Custom lengths can be provided based on specific requirements.

- Tolerances Manufactured to precise dimensional tolerances to meet the specific needs of various applications.

4. Properties

- Strength Varies depending on the steel grade and heat treatment. Generally includes high tensile strength, yield strength, and hardness.

- Machinability Generally good, with variations depending on the grade. Some grades, such as carbon steels, are easier to machine compared to high-alloy steels.

- Durability High durability and resistance to wear and tear, with specific properties tailored to the intended use.

5. Applications

- Engineering and Manufacturing Used in the production of mechanical components such as shafts, gears, and pins.

- Construction Employed in structural applications, including supports, frames, and reinforcements.

- Automotive Utilized for automotive parts that require high strength and reliability, such as axles and crankshafts.

- Tooling Used in the manufacture of tools and dies due to its strength and ability to hold precise tolerances.

6. Finishes and Coatings

- Surface Finish Round bars can come in various finishes, such as hot-rolled, cold-drawn, or ground, depending on the application and required surface quality.

- Coatings Additional coatings or treatments may be applied to enhance corrosion resistance or other specific properties.

7. Standards and Compliance

- Standards Produced according to European standards, such as those defined by EN (European Norm) or ISO (International Organization for Standardization). These standards specify the chemical composition, mechanical properties, and testing methods for the steel.

- Certification Quality certifications may be provided to verify compliance with relevant standards and performance criteria.

8. Advantages

- Versatility Suitable for a wide range of applications due to the variety of grades and dimensions available.

- Strength and Durability Provides high strength and durability, making it suitable for demanding applications.

- Customizable Available in various sizes and finishes to meet specific design and performance requirements.

EN Series Steel Round Bars are critical in many industrial and engineering applications, valued for their strength, precision, and adaptability to various manufacturing and construction needs.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free