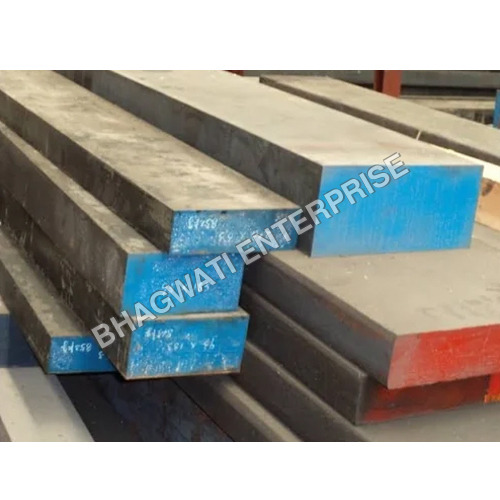

EN31 Alloy Alloy Flat Bar

EN31 Alloy Alloy Flat Bar Specification

- Product Name

- Other

- Steel Type

- Alloy Steel

- Steel Product Type

- Steel Bars

- Grade

- EN31

- Surface

- Polished

- Application

- Construction

EN31 Alloy Alloy Flat Bar Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Lab T.C.

About EN31 Alloy Alloy Flat Bar

Bhagwati Enterprise, Established in1992at Vadodara in Gujarat, is a leading Exporter,Importer,Distributor,Supplier,Trading Company ofFocusing on a customer-centric approach,

-

EN31 Steel Flats manufacturers in India

-

high-performance mold steel.

-

Dealers of EN31 Steel Round , Flat bars, Rectangular bars, Hex bars,

-

EN31 Flat Bar

-

EN31 Steel Flat Bar

-

EN31 Bright Flat Bar

-

EN31 Alloy Steel Bar

-

EN31 Tool Steel Flat

-

EN31 Forged Flat Bar

-

EN31 Rectangular Steel Bar

-

EN31 Steel Bar Supplier

-

EN31 Steel Flat Manufacturer

-

EN31 Bar Price in India

-

EN31 Steel Flat Bar India

-

EN31 Flat Bar Supplier in India

-

Buy EN31 Steel Online India

-

EN31 Steel Bar Exporter India

-

EN31 Tool Steel India

-

EN31 Price per Kg in India

-

EN31 Wholesale Market India

-

EN31 Flat Bar Dealers India

- Buy EN31 Tool Steel Flat Bars in India.

- High Carbon alloy Steel,

| Material | Alloy Steel |

| Thickness | 20 mm |

| Usage/Application | Manufacturing |

| Single Piece Lengh | 6 meter |

| Surface Finish | Polished |

| Brand | Bhagwati Enterprise |

| Material Grade | EN31 |

| Shape | Rectangular |

| Country of Origin | Made in India |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flat Bars Category

EN19 Alloy Steel Flat

Price 90 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Industrial

Grade : SAE 8620

Steel Type : Alloy Steel

Steel Product Type : Steel Plates

EN24 Alloy Steel Flats

Price 110.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Construction

Grade : EN19

Steel Type : Alloy Steel

Steel Product Type : Steel Bars

Wps Flat For Plastic Mould Steel

Price 180.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Construction

Grade : WPS

Steel Type : Tool Steel

Steel Product Type : Steel Bars

Stainless Steel Forged Flat Bar

Price 230.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Construction

Grade : EN24

Steel Type : Stainless Steel

Steel Product Type : Steel Bars

Send Inquiry

Send Inquiry Send SMS

Send SMS