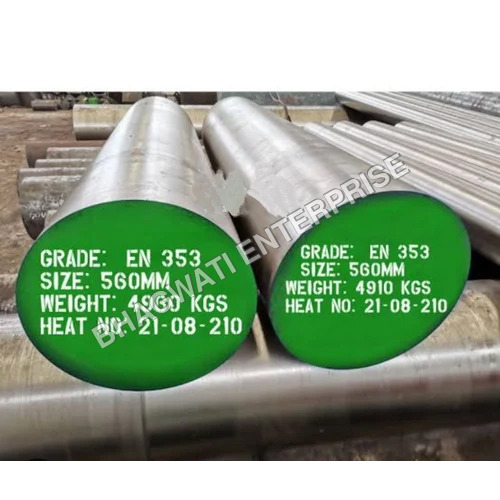

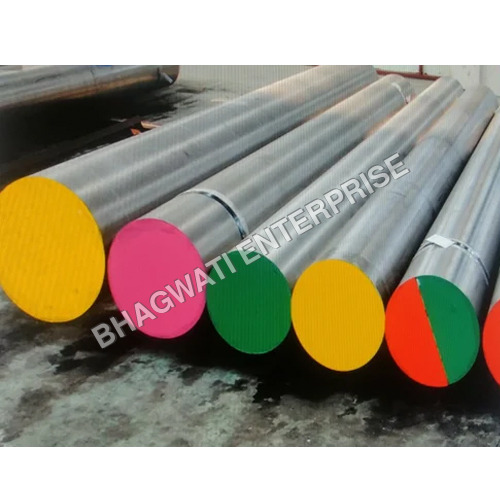

EN353 Case Hardening Steel Round Bar

EN353 Case Hardening Steel Round Bar Specification

- Diameter

- 25 To 300mm Millimeter (mm)

- Specific Use

- For construction

- Grade

- EN353

- Material

- EN353 Round

- Processing

- Heat rolled

- Length

- 6 Meter (m)

- Type

- Round bar

- Finish

- Polished

EN353 Case Hardening Steel Round Bar Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose/ Packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Mill T.C./ Lab T.C. / Ultrasonic Reports

About EN353 Case Hardening Steel Round Bar

About Our Company Leveraging on our vast Industrial Experience We Bhagwati Enterprise, are acknowledged as one of the leading Supplier, Exporter, Trader, Importer & Wholesaler/Distributor of the Industry. Since 1992 we are dealing in a broad assortment of Alloy Steel, Tool Steel, Die Steel, Steel Bars, Carbon Steel Round Bars, SAE 8620 Steel Round Bars, EN Series Steel Round Bars, , AISI Series Steel Round Bars, Flat Bars, Free Cutting Steel, Steel Plates & Nitriding Steel. House Of MS Seamless Pipe To maintain the flawless of the products our Vendors Employ Cutting edge technology and tools in the manufacturing process. After this, all these products.

EN353 isa high-strength, case-hardening steel alloy, hardened and tempered before delivery, featuring nickel, chromium, and molybdenum for excellent tensile strength, ductility, and wear resistance, commonly used for parts requiring high surface hardness and core toughness.Here's a more detailed description of EN353 case-hardening steel bars:Key Characteristics:

- Case-Hardening Steel:EN353 is designed for case hardening, a heat treatment process that creates a hard, wear-resistant surface layer while maintaining a tough core.

- High Strength and Hardness:The combination of nickel, chromium, and molybdenum allows EN353 to achieve high tensile strength and hardness after heat treatment.

- Good Ductility and Toughness:Despite its high strength, EN353 retains good ductility and toughness, making it suitable for applications requiring resistance to impact and fatigue.

- Wear Resistance:The hardened surface layer provides excellent wear resistance, making EN353 ideal for components subjected to high stress and friction.

- Low Carbon Content:EN353 has a relatively low carbon content, which contributes to its good hardenability and machinability.

- Applications:EN353 is commonly used for gears, shafts, axles, connecting rods, and other machine parts where high surface hardness and core toughness are essential.

-

Alloy Steel Round Bar

-

Alloy Steel Rod

-

EN Series Round Bar -EN8,EN9, EN24, EN19, EN31 Round Bar)

-

Chrome Moly Round Bar - ASTM A182 F11 / F22

-

Forged Alloy Steel Round Bar

-

Heat Treated Alloy Steel Rod

-

Precision Ground Alloy Round Bar

-

Annealed Alloy Steel Bar

-

Hardened Alloy Steel Rod

-

Alloy Steel Bar for Auto Components

-

Engineering Grade Alloy Round Rod

-

Heavy Machinery Alloy Steel Bar

-

Oil & Gas Alloy Steel Rod

-

Aerospace Alloy Round Bar

-

Alloy Steel Shafts and Axles

-

Tool Steel Round Bar Supplier

- EN353 Round Bar Suppliers in India

- EN353 Bar Stockists in Vadodara

- EN353 Round Bar Exporters

- EN353 Alloy Bar Distributors in Gujrat

- EN353 Bar Price per Kg

- Ready Stock EN353 Bars

- Buy EN353 Round Bar Online

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Bars Category

WPS Round Bar

Price 270 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : New

Specific Use : For construction

Grade : D2/ D3

Material : Die Steel

Hard Chrome Round Bar

Price 580.00 INR / Kilometer

Minimum Order Quantity : 100 Kilometers

Type : Round bar

Specific Use : For construction

Grade : Fe 500D

Material : Stainless steel

H11 H13 Hot Work Die Steel Bar

Price 230 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Round bar

Specific Use : For construction

Grade : H11 H13

Material : Stainless steel

Die Block Steel DB-6 Round Bar

Price 190 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Round bar

Specific Use : For construction

Grade : DB6

Material : Die Steel Db6

Send Inquiry

Send Inquiry Send SMS

Send SMS