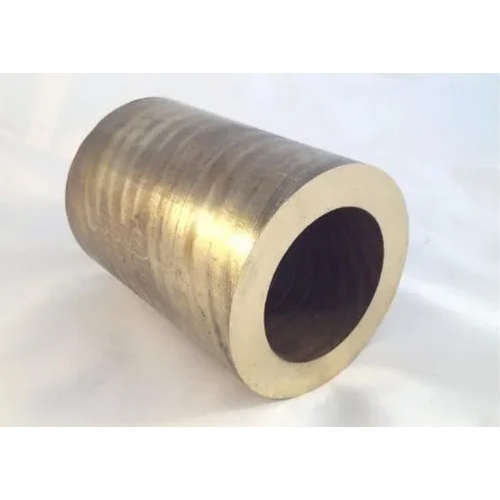

Gun Metal Bush

Product Details:

- Product Type Metal Bush

- Usage Industrial

- Size Customer Requrtment

- Type Other

- Material Gun Metal

- Hardness 65 to 74

- Finish Coated

- Click to View more

Gun Metal Bush Price And Quantity

- 980.00 - 1000.00 INR/Kilograms

- 100 Kilograms

- 980 INR/Kilograms

Gun Metal Bush Product Specifications

- Gun Metal

- Metal Bush

- Other

- Customer Requrtment

- 65 to 74

- Industrial

- Coated

Gun Metal Bush Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- 3 Days

- Sample costs shipping and taxes has to be paid by the buyer

- Asia

- All India

Product Description

Gun metal bushes are components made from a specific type of bronze alloy known as gunmetal, which is used in various mechanical and industrial applications due to its excellent wear resistance, machinability, and durability. Here™s a detailed description:

Composition

- Copper (Cu) 85% to 90%, serves as the primary metal and provides the base for the alloy.

- Tin (Sn) 5% to 10%, enhances strength and corrosion resistance.

- Zinc (Zn) 3% to 7%, added to improve machinability and casting properties.

- Lead (Pb) Up to 5%, often included to improve machinability and provide self-lubricating properties.

- Additional Elements May include small amounts of other elements like iron (Fe) or nickel (Ni) to fine-tune properties.

Properties

- Wear Resistance High resistance to wear and abrasion, making it suitable for applications involving friction.

- Corrosion Resistance Good resistance to corrosion, particularly in environments with exposure to water and mild chemicals.

- Machinability Excellent machinability due to the lead content, which makes it easy to cut, drill, and shape.

- Tensile Strength Provides good tensile strength, which supports its use in load-bearing applications.

- Ductility Offers good ductility, allowing it to withstand deformation without breaking.

Applications

- Bushings and Bearings Commonly used in bushings, bearings, and sleeves where high wear resistance is required.

- Valves and Fittings Employed in the manufacture of valves, fittings, and other components that need to resist wear and corrosion.

- Pumps and Machinery Utilized in components for pumps and machinery, where durability and reliability are critical.

- Marine and Automotive Applied in marine and automotive parts where exposure to harsh environments is common.

Manufacturing Process

- Casting Gun metal can be cast into various shapes, including bushings, using techniques such as sand casting or die casting.

- Machining After casting, the components are machined to precise dimensions using processes such as turning, drilling, and grinding.

- Finishing May include surface treatments such as polishing or coating to achieve the desired surface finish and performance characteristics.

Advantages

- Durability High durability and wear resistance, extending the service life of components.

- Lubrication Self-lubricating properties due to the lead content, reducing the need for additional lubrication.

- Corrosion Resistance Adequate corrosion resistance for many applications, reducing the frequency of maintenance and replacement.

Disadvantages

- Lead Content The presence of lead, while beneficial for machinability and lubrication, can be a concern in some applications due to environmental and health regulations.

- Cost Can be more expensive compared to other materials like standard bronze or brass due to the alloying elements and manufacturing processes.

Gun metal bushes are essential in applications where high performance and reliability are required, particularly in environments involving high wear and corrosion. Their unique properties make them suitable for a range of industrial and mechanical uses.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free