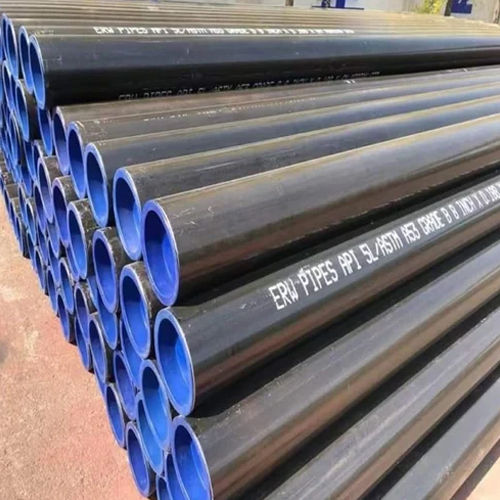

Jindal Ms Black ERW Pipe

Product Details:

- Application Construction Structure Pipe Oil Pipe Fluid Pipe Hydraulic Pipe Boiler Pipe Gas Pipe

- End Protector Plastic Pipe Cap

- Feature High quality

- Material Mild Steel

- Product Type Mild Steel Pipes

- Type Welded

- Shape Round

- Click to View more

Jindal Ms Black ERW Pipe Price And Quantity

- 100 Kilograms

- 75 INR/Kilograms

Jindal Ms Black ERW Pipe Product Specifications

- Construction Structure Pipe Oil Pipe Fluid Pipe Hydraulic Pipe Boiler Pipe Gas Pipe

- Mild Steel

- Welded

- Hot Rolled

- 6 Meter (m)

- Plastic Pipe Cap

- ERW

- All Size

- Other

- High quality

- Round

- Mild Steel Pipes

Jindal Ms Black ERW Pipe Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cash Against Delivery (CAD) Cash on Delivery (COD) Cheque

- 5000 Kilograms Per Month

- Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia

- All India

- Mill T.C./ Lab T.C.

Product Description

Jindal Black Pipe refers to black steel pipes produced by Jindal, a prominent manufacturer in the steel industry. These pipes are widely used in various applications due to their strength, durability, and cost-effectiveness. Here's a detailed description:

Jindal Black Pipe Description

1. Material

- Composition Made from carbon steel, with a carbon content typically up to 0.3%. This composition gives the pipe good strength and machinability while remaining cost-effective.

- Finish The term "black pipe" refers to the pipe's appearance due to its dark, oily coating from the manufacturing process. This coating provides a level of protection against corrosion during storage and transportation.

2. Manufacturing Process

- Production Jindal black pipes are usually produced by hot-rolling or cold-rolling processes. These processes involve forming steel into pipes either through extrusion, welding, or seamless methods.

- Seamless vs. Welded

- Seamless Made from a solid billet of steel that is heated and formed into a pipe without welding. This type is stronger and more reliable for high-pressure applications.

- Welded Produced by rolling steel sheets into a cylindrical shape and welding the seam. Suitable for general-purpose applications but may have weaker points at the weld.

3. Shape and Dimensions

- Shape Cylindrical with a hollow, round cross-section.

- Diameter Available in a range of outer diameters, from a few millimeters to several inches.

- Thickness Varies depending on the application, from thin-walled to thick-walled options.

- Length Typically supplied in standard lengths, such as 6 to 12 meters (20 to 40 feet), but custom lengths are available.

4. Properties

- Strength Offers good tensile and yield strength, suitable for a variety of applications where high strength is required.

- Corrosion Resistance Black pipes have limited corrosion resistance due to the lack of a protective coating. They may need additional treatment or coating for use in environments exposed to moisture or corrosive elements.

- Weldability Generally easy to weld, which makes them suitable for various construction and manufacturing applications.

5. Applications

- Construction Used for structural purposes, such as supports, frames, and scaffolding.

- Plumbing Commonly used for water and gas pipelines in residential and commercial plumbing systems.

- Industrial Employed in machinery, equipment, and infrastructure for transporting fluids and gases.

- Automotive Utilized in automotive components and other manufacturing processes.

6. Finishes and Coatings

- Surface Finish The "black" finish is typically a result of the pipe being coated with a protective layer during manufacturing. However, additional coatings or treatments may be applied for enhanced protection.

- Coatings May be coated or painted as needed to improve corrosion resistance and durability, especially for outdoor or exposed applications.

7. Standards and Compliance

- Standards Manufactured according to industry standards such as ASTM (American Society for Testing and Materials) or IS (Indian Standards), ensuring consistent quality and performance.

- Certification Quality certifications may be available, indicating compliance with specific performance and safety standards.

8. Advantages

- Cost-Effective Generally more affordable compared to stainless steel and other specialty pipes.

- Versatility Suitable for a wide range of applications due to its strength, durability, and ease of fabrication.

- Availability Widely available in various sizes and dimensions to meet diverse requirements.

Jindal Black Pipes are valued for their reliability, strength, and cost-effectiveness, making them a popular choice for numerous industrial, construction, and plumbing applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free