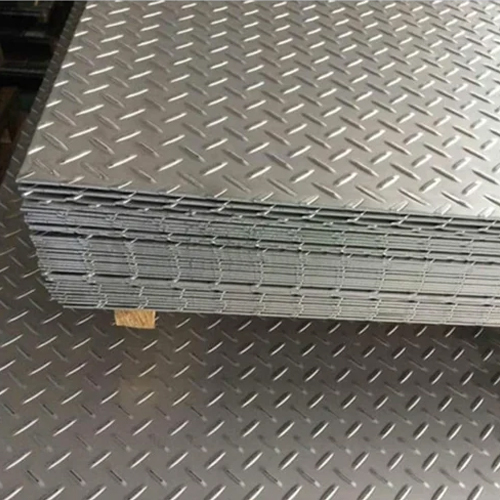

Mild Steel Plate

Product Details:

- Product Name Other

- Steel Type Mild Steel

- Grade IS2062 Grade

- Shape Plate

- Surface Polished

- Application Construction

- Click to View more

Mild Steel Plate Price And Quantity

- 100 Kilograms

- 75 INR/Kilograms

Mild Steel Plate Product Specifications

- Construction

- Plate

- IS2062 Grade

- Mild Steel

- Polished

- Other

Mild Steel Plate Trade Information

- 5000 Kilograms Per Month

- Days

- Loose

- Asia

- All India

- Mill T.C.

Product Description

Mild steel plates are flat pieces of steel with relatively low carbon content, making them suitable for a wide range of applications due to their good machinability, weldability, and formability. They are commonly used in structural, manufacturing, and construction projects.

Composition

- Material Mild steel, also known as low-carbon steel, typically contains:

- Carbon (C) 0.05% to 0.25%

- Manganese (Mn) 0.30% to 0.90%

- Silicon (Si) Up to 0.35%

- Phosphorus (P) and Sulfur (S) Max 0.05% each

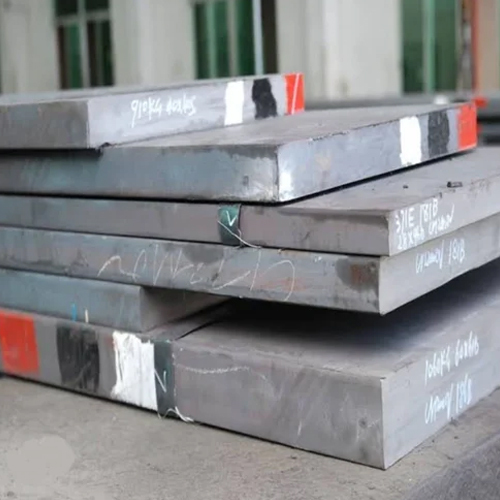

Specifications

- Thickness Mild steel plates are available in various thicknesses, commonly from 3 mm to 100 mm or more, depending on the application.

- Dimensions Standard dimensions for mild steel plates include:

- Width Typically ranges from 1000 mm to 3000 mm.

- Length Usually available in lengths of 2000 mm to 6000 mm, with custom sizes possible.

- Grades Commonly specified grades include:

- IS 2062 (India) Structural steel for general purposes.

- ASTM A36 (USA) General-purpose carbon steel with good weldability and machinability.

- EN 10025 (Europe) Standards for hot-rolled structural steel.

Properties

- Strength Mild steel plates offer moderate tensile and yield strength, suitable for many structural and engineering applications.

- Ductility High ductility allows for easy bending, forming, and shaping without cracking.

- Machinability Good machinability makes it easy to cut, drill, and weld.

- Weldability Excellent weldability, making it suitable for fabrication and assembly processes.

Applications

- Construction Used in the construction of buildings, bridges, and other infrastructure projects as beams, columns, and structural supports.

- Manufacturing Applied in the production of various machinery components, including frames, panels, and parts.

- Automotive Utilized in automotive manufacturing for parts such as body panels, chassis components, and structural elements.

- General Fabrication Employed in general fabrication projects, including furniture, storage solutions, and industrial equipment.

Manufacturing Process

- Steelmaking Produced from raw materials in a basic oxygen furnace or electric arc furnace.

- Rolling Hot-rolled or cold-rolled into plates of specified thickness and dimensions.

- Finishing Plates may undergo finishing processes such as cutting, surface treatment, or coating to meet specific requirements.

Advantages

- Cost-Effective More affordable compared to higher-carbon or alloy steels due to simpler production processes.

- Versatility Can be used in a wide range of applications due to its flexibility and ease of fabrication.

- Ease of Use Simple to work with, including cutting, welding, and machining.

Disadvantages

- Corrosion Resistance Prone to rust and corrosion if not protected, especially in outdoor or harsh environments. May require coating or painting for protection.

- Strength Limitations While adequate for many applications, it may not offer the high strength or hardness of higher-carbon or alloy steels for more demanding uses.

Mild steel plates are a fundamental material in various industries due to their balance of strength, ductility, and affordability, making them suitable for a broad spectrum of applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS