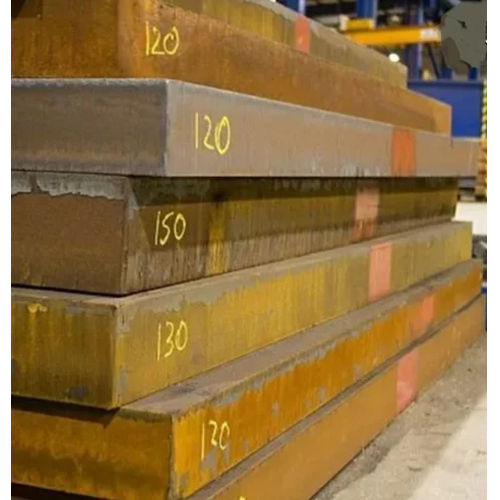

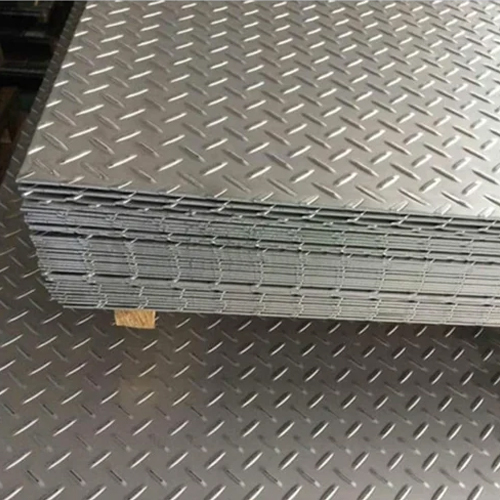

MS Heavy Duty Plate

Product Details:

- Product Name Other

- Steel Type Mild Steel

- Grade Mild Steel

- Shape Plate

- Surface Coated

- Application Construction

- Click to View more

MS Heavy Duty Plate Price And Quantity

- 100 Kilograms

- 85 INR/Kilograms

- 85.00 - 90.00 INR/Kilograms

MS Heavy Duty Plate Product Specifications

- Construction

- Mild Steel

- Plate

- Other

- Coated

- Mild Steel

MS Heavy Duty Plate Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- Days

- Sample costs shipping and taxes has to be paid by the buyer

- Loose

- Asia

- All India

- Mill T.C.

Product Description

Mild steel heavy duty plates are robust steel plates used in a variety of applications requiring high strength and durability. These plates are characterized by their thickness and ability to withstand heavy loads and stresses. Here™s a detailed description:

Composition

- Material Mild steel, also known as low-carbon steel, generally contains:

- Carbon (C) 0.05% to 0.25%

- Manganese (Mn) 0.30% to 0.90%

- Silicon (Si) Up to 0.35%

- Phosphorus (P) and Sulfur (S) Max 0.05% each

Specifications

- Thickness Heavy duty plates are typically thicker than standard plates, ranging from 6 mm to 100 mm or more, depending on the application and requirements.

- Dimensions Common dimensions include standard widths and lengths, such as 1000 mm to 3000 mm in width and 2000 mm to 6000 mm in length, though custom sizes can be provided.

- Grades Mild steel plates are available in various grades, often specified by standards such as IS 2062 (India), ASTM A36, or EN 10025 (European standards).

Properties

- Strength Provides high tensile and yield strength, making it suitable for structural applications and heavy-duty use.

- Ductility Offers good ductility, allowing it to be formed and welded easily without cracking.

- Toughness Exhibits toughness, meaning it can absorb impact and stress without failing.

- Machinability Can be easily machined, cut, and welded, making it versatile for various fabrication processes.

Applications

- Construction Used in construction for structural elements such as beams, columns, and supports.

- Heavy Machinery Applied in the manufacturing of heavy machinery and equipment components.

- Transport Utilized in the fabrication of transport vehicles, including trucks and trailers.

- Mining and Industrial Employed in mining equipment, industrial machinery, and other heavy-duty applications.

Manufacturing Process

- Steelmaking The mild steel is produced through processes such as basic oxygen steelmaking or electric arc furnace.

- Rolling The steel is rolled into plates of desired thickness through hot rolling or cold rolling processes.

- Heat Treatment Depending on the application, the plates may undergo heat treatment to enhance their mechanical properties.

Advantages

- Cost-Effective Generally more affordable than high-carbon or alloy steels while still offering substantial strength and durability.

- Versatile Can be used in a wide range of applications due to its workability and strength.

- Ease of Fabrication Easily machined, welded, and cut, making it suitable for various fabrication processes.

Disadvantages

- Corrosion Resistance Mild steel plates are susceptible to rust and corrosion if not properly protected or coated, especially in harsh environments.

- Strength Limitations While strong, it may not offer the same level of strength as higher-grade steels or alloys for extreme applications.

Mild steel heavy duty plates are integral to many industries where strength, durability, and versatility are essential, providing a reliable and cost-effective solution for a wide range of structural and industrial needs.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free