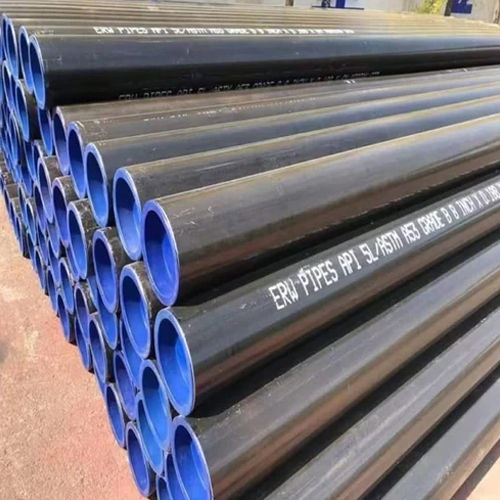

MS Seamless Pipes

Product Details:

- Material Mild Steel

- Feature Strong, Durable

- Surface Finish Annealing

- Application Construction Gas Pipe Oil Pipe Chemical Fertilizer Pipe Hydraulic Pipe Structure Pipe

- Product Type Mild Steel Pipes

- Type Seamless

- Shape Round

- Click to View more

MS Seamless Pipes Price And Quantity

- 95 INR/Kilograms

- 100 Kilograms

- 95.00 - 100.00 INR/Kilograms

MS Seamless Pipes Product Specifications

- A106 Gr.B

- Round

- Construction Gas Pipe Oil Pipe Chemical Fertilizer Pipe Hydraulic Pipe Structure Pipe

- All Size

- Annealing

- Strong, Durable

- ASTM A53-2007

- Mild Steel Pipes

- Mild Steel

- Other

- Hot Rolled

- 6 Meter (m)

- Seamless

MS Seamless Pipes Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Loose

- Asia

- All India

Product Description

Certainly! Here™s a detailed description of Mild Steel Seamless Pipes

Mild Steel Seamless Pipe Description

1. Material

- Composition Mild steel (also known as low carbon steel) typically contains up to 0.3% carbon by weight. It may include other elements like manganese, silicon, and small amounts of other alloys.

- Properties Known for its good weldability, machinability, and ductility, mild steel is less strong than high-carbon steels but offers excellent formability.

2. Manufacturing Process

- Seamless Production The pipe is made from a solid billet of mild steel. The billet is heated to a high temperature and then pierced to create a hollow tube. This tube is then elongated and reduced to the desired diameter and wall thickness through processes such as extrusion, rotary piercing, or elongation.

- No Welds or Joints Unlike welded pipes, seamless pipes are produced without any welds or joints, which eliminates weak points and enhances their ability to handle high pressure and stress.

3. Shape and Dimensions

- Shape Cylindrical with a hollow, round cross-section.

- Diameter Available in a variety of outer diameters and wall thicknesses, from a few millimeters to several inches. Custom sizes can be produced upon request.

- Length Typically supplied in standard lengths, such as 6 to 12 meters (20 to 40 feet), but custom lengths are also available.

4. Properties

- Strength Provides moderate tensile and yield strength, suitable for many general applications but not as strong as some alloy steels.

- Corrosion Resistance Mild steel has limited resistance to corrosion, so it may require protective coatings or painting to prevent rust, especially in exposed environments.

- Ductility High ductility allows the pipe to be easily formed and bent without cracking, making it ideal for various manufacturing processes.

5. Applications

- Structural Used in construction for structural components like supports, beams, and columns.

- Piping Systems Employed in piping for water supply, gas distribution, and other fluid handling systems where high pressure and integrity are required.

- Automotive and Machinery Utilized in automotive and machinery components due to its machinability and moderate strength.

- General Manufacturing Suitable for a wide range of general-purpose applications where high strength is not the primary requirement.

6. Finishes and Coatings

- Surface Finish Can come in various finishes, such as hot-rolled or cold-drawn, depending on the production process and requirements.

- Coatings Often coated or painted to improve corrosion resistance and durability, especially for outdoor or industrial use.

7. Standards and Compliance

- Standards Manufactured to meet various international standards such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), or equivalent national standards.

- Certification Quality certifications may be provided to ensure that the pipes meet specific performance and safety criteria.

8. Advantages

- Uniformity Seamless pipes offer uniformity in strength and wall thickness without the weak points associated with welds.

- Pressure Handling Suitable for applications requiring higher pressure and stress tolerance.

Mild steel seamless pipes are valued for their durability, consistency, and versatility across a wide range of industries and applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free