P20 Plastic Mould Steel Bar

Product Details:

- Finish Black

- Application Plastic Mould Die

- Specific Use For Plastic Mould Industry

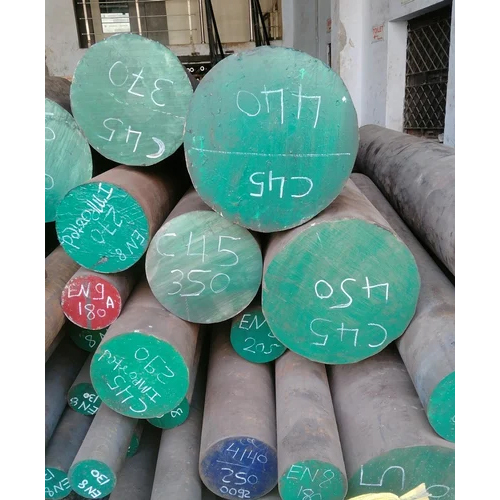

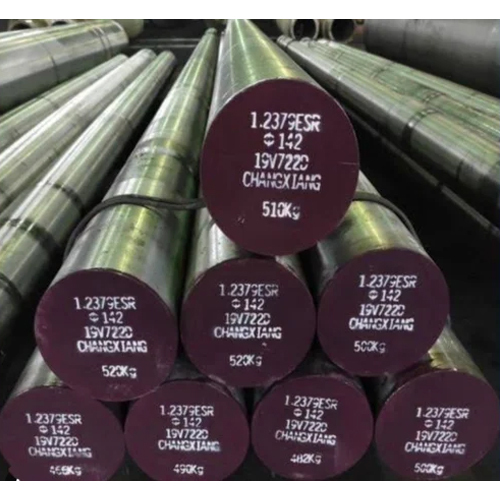

- Type Round bar

- Length 6 Meter (m)

- Material Mould steel P20

- Grade P20

- Click to View more

P20 Plastic Mould Steel Bar Price And Quantity

- 230 INR/Kilograms

- 100 Kilograms

P20 Plastic Mould Steel Bar Product Specifications

- P20

- Mould steel P20

- 6 Meter (m)

- Round bar

- For Plastic Mould Industry

- Black

- Plastic Mould Die

P20 Plastic Mould Steel Bar Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Loose

- Asia

- All India

- Mill T.C./ Lab T.C. / Ultrasonic Reports

Product Description

P20 Plastic Mould Steel is a type of tool steel specifically designed for the manufacture of plastic moulds. It is well-regarded for its balance of toughness, machinability, and ease of heat treatment, making it suitable for high-precision moulding applications. Here™s a detailed description:

P20 Plastic Mould Steel Description

1. Material

- Composition P20 steel is an alloy steel that typically contains carbon, chromium, molybdenum, and vanadium. The general composition includes:

- Carbon (C) Approximately 0.35-0.45%

- Chromium (Cr) About 1.4-1.6%

- Molybdenum (Mo) Around 0.9-1.2%

- Vanadium (V) Small amounts, typically up to 0.2%

- Properties This composition provides a good combination of hardness, toughness, and resistance to wear, making P20 suitable for various mould-making applications.

2. Manufacturing Process

- Production P20 mould steel is typically produced by melting and alloying the steel, followed by hot rolling or forging into blocks or bars. It can then be machined into precise mould components.

- Heat Treatment P20 steel is often pre-hardened during production, which reduces the need for additional heat treatment. It is commonly supplied in a hardness range of 280-320 HB (Brinell Hardness). However, it can be further heat-treated to achieve specific hardness and mechanical properties if required.

3. Shape and Dimensions

- Shape Typically supplied in rectangular or square blocks, or round bars, which are then machined into mould components.

- Dimensions Available in various sizes, including thicknesses ranging from a few millimeters to several centimeters, and lengths or diameters according to specific needs. Custom sizes can be produced based on mould design requirements.

4. Properties

- Hardness Generally pre-hardened to a Brinell hardness of 280-320 HB, providing good wear resistance and dimensional stability.

- Machinability Offers excellent machinability, allowing for precise fabrication of intricate mould designs and features.

- Toughness Provides a good balance of toughness and hardness, which is crucial for mould durability and performance.

- Polishability Excellent surface finish and polishability, which is important for producing high-quality plastic parts with smooth surfaces.

5. Applications

- Plastic Moulds Used in the production of moulds for various plastic parts, including automotive components, consumer products, and industrial parts.

- Tooling Employed in the manufacture of tooling and dies where precision and durability are essential.

- Injection Moulding Commonly used in injection moulding applications where high-quality surface finishes and resistance to wear are required.

6. Finishes and Coatings

- Surface Finish Can be supplied with a variety of surface finishes, including as-cast, ground, or polished, depending on the application and requirements.

- Coatings Moulds made from P20 steel may be coated or treated with surface hardening processes to enhance wear resistance and reduce friction.

7. Standards and Compliance

- Standards P20 steel conforms to various international standards, such as ASTM A681 or equivalent standards, which specify the chemical composition, mechanical properties, and quality requirements.

- Certification Quality certifications are often provided to verify compliance with industry standards and performance criteria.

8. Advantages

- Versatility Suitable for a wide range of plastic moulding applications due to its balanced properties.

- Ease of Machining Provides ease of machining and polishing, which is important for achieving precise mould designs and high-quality surface finishes.

- Durability Offers good wear resistance and toughness, contributing to the longevity of moulds and tools.

P20 Plastic Mould Steel is a highly regarded material for the manufacturing of plastic moulds, valued for its combination of hardness, machinability, and durability. Its ability to maintain precision and provide a high-quality finish makes it an excellent choice for producing detailed and complex moulds.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free