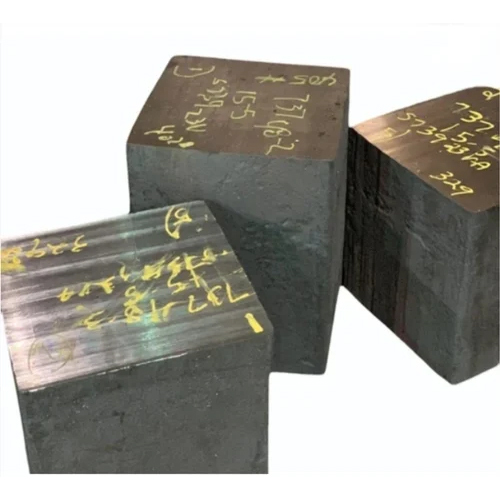

Plastic Mould Steel Block

Product Details:

- Product Name Other

- Steel Type Stainless Steel

- Grade P20

- Surface Polished

- Application Other

- Click to View more

Plastic Mould Steel Block Price And Quantity

- 100 Kilograms

- 280 INR/Kilograms

Plastic Mould Steel Block Product Specifications

- Other

- Polished

- Other

- Stainless Steel

- P20

Plastic Mould Steel Block Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- 1 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Loose

- Asia

- All India

- Mill T.C./ Lab T.C.

Product Description

Plastic Mould Steel Block Description

Product Name Plastic Mould Steel Block

Material High-Quality Steel Specifically Designed for Plastic Moulding Applications

Common Grades

- P20 A common grade of plastic mould steel known for its good machinability and hardness.

- P21 Similar to P20 but often used for more demanding applications due to slight differences in alloying elements.

- H13 A tool steel known for high hardness, wear resistance, and heat resistance, used for high-performance moulds.

- 420 A stainless steel variant with good corrosion resistance and hardness.

Specifications

- Dimensions Available in various sizes and shapes, such as blocks, plates, and billets. Custom sizes may be available.

- Surface Finish Typically supplied in a rough, as-rolled, or machined finish, depending on requirements.

Properties

- Hardness Generally high, ensuring durability and resistance to wear and deformation. Hardness values may vary depending on the grade and heat treatment.

- Tensile Strength High tensile strength to withstand the pressures and stresses involved in the moulding process.

- Machinability Good machinability for precision engineering and tooling. Some grades are specifically designed to be easy to machine.

- Thermal Conductivity Depending on the grade, may have high thermal conductivity to help manage heat during the moulding process.

Key Features

- Durability Designed to endure the high pressures and temperatures typical of plastic moulding operations.

- Wear Resistance High wear resistance to extend the life of the mould and maintain high-quality output.

- Heat Resistance Certain grades like H13 offer excellent heat resistance, crucial for high-temperature moulding applications.

- Corrosion Resistance Some grades, such as stainless steel variants, offer improved resistance to corrosion.

Applications

- Plastic Injection Moulding Used to create moulds for producing plastic parts and products.

- Blow Moulding Applied in the manufacturing of hollow plastic products.

- Compression Moulding Suitable for creating parts from thermosetting plastics.

- Die Casting Used for moulds in die-casting operations for various non-ferrous metals.

Fabrication

- Machining Can be machined using standard techniques, with particular attention required for maintaining dimensional accuracy.

- Heat Treatment May undergo heat treatment processes to achieve desired hardness and mechanical properties.

- Polishing Surface polishing or finishing may be required for high-precision applications or for achieving a specific surface quality.

Standards and Specifications

- Industry Standards Typically conforms to industry standards such as ASTM, DIN, or JIS, depending on the region and specific application.

- Certifications May come with certifications to ensure quality and compliance with relevant specifications.

Supplier Information

- Manufacturers Sourced from reputable steel manufacturers or suppliers specializing in mould steel.

- Customization Custom sizes and grades may be available upon request to meet specific needs.

Plastic mould steel blocks are essential for producing high-quality plastic components and are chosen based on their ability to withstand the stresses of the moulding process while maintaining precision and durability.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free