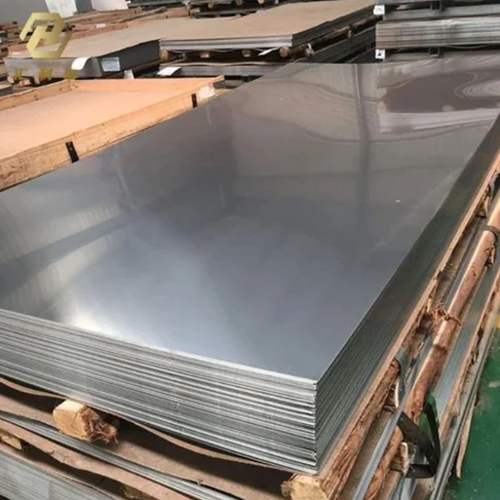

Stainless Steel 316Circle

Product Details:

- Steel Type Stainless Steel

- Grade SS 304/304L/ 316/ 316L

- Application Other

- Click to View more

Stainless Steel 316Circle Price And Quantity

- 100 Kilograms

- 265 INR/Kilograms

Stainless Steel 316Circle Product Specifications

- SS 304/304L/ 316/ 316L

- Other

- Stainless Steel

Stainless Steel 316Circle Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 5000 Kilograms Per Month

- Days

- Loose

- All India

Product Description

A stainless steel circle is a flat, circular disc made from stainless steel. It is widely used in various industrial, architectural, and manufacturing applications due to its durability, corrosion resistance, and aesthetic appeal. Here™s a detailed description:

Stainless Steel Circle Description

1. Material

- Composition Made from stainless steel, which is an alloy of iron with at least 10.5% chromium and may also include other elements like nickel, molybdenum, and titanium. This composition gives the circle its excellent corrosion resistance, strength, and resistance to staining.

- Grades Common grades include 304 (general-purpose), 316 (marine-grade with enhanced corrosion resistance), and others based on specific needs and applications.

2. Manufacturing Process

- Cutting and Shaping Stainless steel circles are typically produced by cutting or stamping flat sheets of stainless steel into circular shapes. This can be done through processes like shearing, laser cutting, or water jet cutting.

- Surface Finish The surface finish can be varied according to the desired application, including polished, brushed, or matte finishes.

3. Shape and Dimensions

- Shape Flat, circular disc with a uniform thickness.

- Diameter Available in a wide range of diameters, from small circles a few centimeters across to large discs several meters in diameter.

- Thickness Varies depending on the application, from thin discs used in decorative applications to thick plates used in structural or industrial applications.

4. Properties

- Corrosion Resistance High resistance to oxidation and rust, making it suitable for use in harsh environments and for applications where exposure to moisture or chemicals is common.

- Strength Offers good mechanical strength and durability, which can be enhanced by the specific grade of stainless steel used.

- Aesthetic Appeal Provides a clean, modern look, often used in architectural and design applications for its visual appeal.

5. Applications

- Architectural and Decorative Used in architectural features, such as facades, railings, and decorative panels due to its aesthetic quality and resistance to weathering.

- Industrial and Manufacturing Employed in various machinery and equipment parts, including components in pumps, valves, and other industrial devices.

- Construction Utilized in structural applications and as part of fittings and fixtures.

- Kitchenware Often used for making kitchen utensils, appliances, and countertops due to its ease of cleaning and hygienic properties.

6. Finishes

- Polished High-gloss finish for aesthetic purposes, often used in visible applications.

- Brushed A matte finish that reduces glare and is often used in both industrial and decorative applications.

- Matte A non-reflective finish that is used for functional applications where aesthetics are secondary to performance.

7. Standards and Compliance

- Standards May be manufactured to meet specific industry standards, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), depending on the intended use.

- Certification Quality certifications may be available to confirm compliance with specific standards or performance criteria.

8. Advantages

- Durability High resistance to wear and tear, suitable for both indoor and outdoor use.

- Maintenance Easy to clean and maintain, retaining its appearance over time.

- Versatility Can be used in a wide range of applications due to its adaptability to various finishes and sizes.

Stainless steel circles are valued for their strength, corrosion resistance, and versatility, making them a popular choice across multiple industries and applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS