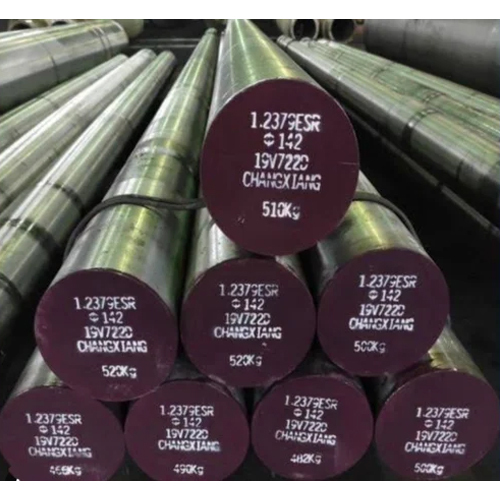

Stainless Steel 410 Round Bar

Product Details:

- Type Round bar

- Finish Polished

- Material Stainless steel

- Specific Use For construction

- Grade 410

- Click to View more

Stainless Steel 410 Round Bar Price And Quantity

- 95.00 - 100.00 INR/Kilograms

- 95 INR/Kilograms

- 100 Kilograms

Stainless Steel 410 Round Bar Product Specifications

- Polished

- For construction

- Stainless steel

- Round bar

- 410

Stainless Steel 410 Round Bar Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cheque

- 5000 Kilograms Per Month

- Days

- Sample costs shipping and taxes has to be paid by the buyer

- Loose/ Bundle

- Asia

- All India

- Mill T.C.

Product Description

Stainless Steel 410 round bars are cylindrical bars made from grade 410 stainless steel, known for its high hardness, wear resistance, and moderate corrosion resistance. They are widely used in applications requiring a balance of strength and resistance to corrosion. Here™s a comprehensive description:

Composition

- Iron (Fe) Base metal.

- Chromium (Cr) 11.5% to 13.5%, which provides corrosion resistance and enhances hardness.

- Carbon (C) 0.08% to 0.15%, which increases hardness and strength.

- Manganese (Mn) Up to 1.0%, improves toughness and machinability.

- Silicon (Si) Up to 1.0%, aids in deoxidization.

- Phosphorus (P) Up to 0.04%, affects hardness and machinability.

- Sulfur (S) Up to 0.03%, improves machinability.

Specifications

- Diameter Typically available in a range of diameters, from as small as 6 mm to over 300 mm, depending on the application and manufacturer.

- Length Common lengths include standard lengths of 3 meters to 6 meters, though custom lengths can be provided.

- Standards Conforms to various standards, including ASTM A276, ASTM A313, and AISI 410.

Properties

- Hardness High hardness due to its chromium content, which allows it to be heat treated to achieve higher hardness levels (up to 58 HRC).

- Corrosion Resistance Moderate resistance to corrosion and oxidation, suitable for mildly corrosive environments. However, it is less resistant compared to austenitic stainless steels like 304 or 316.

- Strength Offers good tensile and yield strength, making it suitable for applications requiring structural integrity.

- Machinability Relatively good machinability compared to other stainless steels, especially in its annealed state.

Applications

- Engineering Components Used in the manufacturing of parts such as valves, shafts, and fasteners where strength and wear resistance are crucial.

- Automotive Parts Employed in automotive components including exhaust valves and pistons.

- Industrial Machinery Applied in various industrial machinery and equipment requiring high strength and moderate corrosion resistance.

- Tools Utilized in the production of tools, particularly those that need a good balance of hardness and wear resistance.

Manufacturing Process

- Melting The stainless steel is melted in an electric arc furnace or similar equipment.

- Forging The molten steel is forged into cylindrical shapes (round bars) using processes such as extrusion or rolling.

- Heat Treatment Round bars may be heat treated to achieve the desired hardness and mechanical properties. Common heat treatments include annealing and quenching.

- Finishing Includes processes such as machining, grinding, and polishing to achieve precise dimensions and surface finish.

Advantages

- Strength and Hardness Provides high strength and hardness, suitable for demanding applications.

- Wear Resistance Excellent resistance to wear, making it suitable for parts subjected to friction and abrasion.

- Good Machinability Easier to machine and fabricate compared to some other stainless steels.

Disadvantages

- Corrosion Resistance While it has some corrosion resistance, it is not as resistant as other stainless steels like 304 or 316, and may require protective coatings in highly corrosive environments.

- Brittleness Can be more brittle compared to austenitic stainless steels, particularly in its hardened state.

Stainless Steel 410 round bars are valued for their strength, hardness, and moderate corrosion resistance, making them a versatile material for a variety of industrial and engineering applications where durability and wear resistance are essential.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free