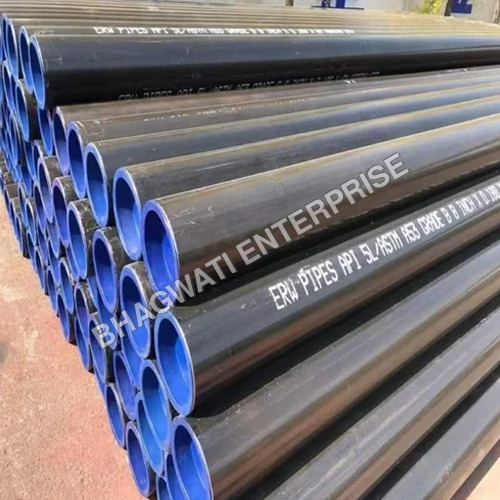

Heavy Wall Thickness Seamless Pipe

Heavy Wall Thickness Seamless Pipe Specification

- Material

- Mild Steel

- Feature

- Strong, Durable

- Application

- Drill Pipe, Construction, Gas Pipe, Hydraulic Pipe, Chemical Fertilizer Pipe, Oil Pipe

- Product Type

- Mild Steel Pipes

- Type

- Seamless

- Shape

- Round

- Technique

- Hot Rolled

- Surface Treatment

- Other

- Grade

- A106 Gr.B

- Size

- All Size

- Length

- 6 Millimeter (mm)

Heavy Wall Thickness Seamless Pipe Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 1 Days

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Heavy Wall Thickness Seamless Pipe

About Our Company Leveraging on our vast Industrial Experience We Bhagwati Enterprise, are acknowledged as one of the leading Supplier, Exporter, Trader, Importer & Wholesaler/Distributor of the Industry. Since 1992 we are dealing in a broad assortment of Alloy Steel, Tool Steel, Die Steel, Steel Bars, Carbon Steel Round Bars, SAE 8620 Steel Round Bars, EN Series Steel Round Bars, , AISI Series Steel Round Bars, Flat Bars, Free Cutting Steel, Steel Plates & Nitriding Steel. House Of MS Seamless Pipe To maintain the flawless of the products our Vendors Employ Cutting edge technology and tools in the manufacturing process. After this, all these products.

Bhagwati EnterpriseWe provide a qualitative range of Heavy Wall Thickness Pipes to our clients, which is offered in heavy wall thickness. Our range is available in OD and ID machined and can be customized as per the clients' requirements. These are widely used for mechanical and structural purposes. Further, our range is available in outer diameter of 200mm OD to 610mm OD and wall thickness of 25mm to 200mm. It is acknowledged for the robust construction and corrosion and abrasion resistance.Clients can avail Heavy Wall Thickness Pipes, that are offered in heavy wall thickness. The product is used for a variety of mechanical and structural purposes. Also, these are offered in heavy wall thickness. The outside diameter available from 200mm OD to 610mm OD and wall thickness from 25mm to 200mm

- Thick Wall Steel Pipe Suppliers In Vadodara.

- Heavy Wall Seamless Pipe Stockists in India

- Thick-Walled Pipe

- Heavy Duty Pipe

- Extra Heavy Pipe

- Industrial Steel Pipes

- Thick Section Pipe.

-

Heavy Gauge Pipe

- MS Seamless Pipe Manufacturers in Vadodara:

- MS Seamless Pipe Suppliers in India:

- Jindal Seamless Pipes:

- Top MS Seamless Pipe Manufacturers:

-

Heavy Thickness Pipe

-

Thick Wall Steel Pipe

-

Heavy Wall Carbon Steel Pipe

-

Extra Heavy Seamless Pipe

-

SCH 160 Pipe / SCH XXS Pipe

-

High Pressure Thick Wall Pipe

-

Heavy Gauge Steel Pipe

-

Industrial Grade Thick Pipe

-

Heavy Thickness Pipe Manufacturer India

Heavy Wall Steel Pipe Distributor in Vadodara

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Seamless Pipe Category

Mild Steel Seamless Pipe

Price 100 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Technique : Hot Rolled

Surface Treatment : Other

Feature : High quality

Length : 4mtr Meter (m)

Jindal Ms Black ERW Pipe

Price 75 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Technique : Hot Rolled

Surface Treatment : Other

Feature : High quality

Length : 6 Meter (m)

MS Seamless Pipes

Price 95 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Technique : Hot Rolled

Surface Treatment : Other

Feature : Strong, Durable

Length : 6 Meter (m)

Send Inquiry

Send Inquiry Send SMS

Send SMS