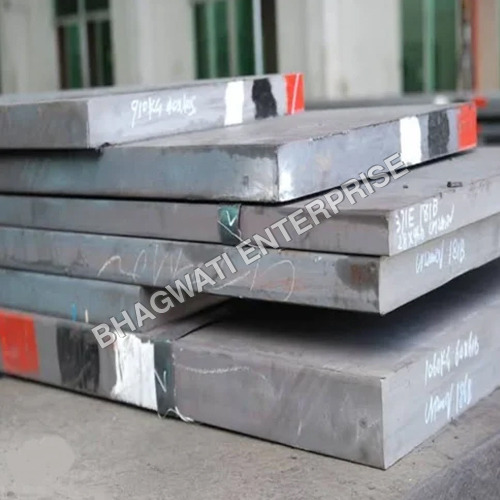

C45 Carbon Steel Plates

C45 Carbon Steel Plates Specification

- Product Name

- Steel

- Steel Type

- Alloy Steel

- Grade

- C45

- Shape

- Plate

- Surface

- Coated

- Application

- Construction

C45 Carbon Steel Plates Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Mill T.C. / Lab T.C.

About C45 Carbon Steel Plates

About Our Company Leveraging on our vast Industrial Experience We Bhagwati Enterprise, are acknowledged as one of the leading Supplier, Exporter, Trader, Importer & Wholesaler/Distributor of the Industry. Since 1992 we are dealing in a broad assortment of Alloy Steel, Tool Steel, Die Steel, Steel Bars, Carbon Steel Round Bars, SAE 8620 Steel Round Bars, EN Series Steel Round Bars, , AISI Series Steel Round Bars, Flat Bars, Free Cutting Steel, Steel Plates & Nitriding Steel. House Of MS Seamless Pipe To maintain the flawless of the products our Vendors Employ Cutting edge technology and tools in the manufacturing process. After this, all these products.

C45 plate profile cuttinginvolves shaping C45 steel plates into specific designs or profiles.C45 steel is a medium-carbon steel known for its strength, hardness, and good machinability, making it suitable for various mechanical parts and components.Profile cutting utilizes methods like flame cutting, plasma cutting, or laser cutting to achieve precise shapes and contours.C45 Steel Properties:

- Composition:C45 steel typically contains around 0.45% carbon, along with manganese, silicon, and other elements.

- Tensile Strength:It has a tensile strength ranging from 570-700 MPa.

- Hardness:In its normalized condition, C45 steel has a Brinell hardness of 170-210 HB.

- Machinability:It is known for good machinability, making it relatively easy to cut and shape.

- Weldability:C45 steel is generally weldable, but precautions may be needed, especially for thicker sections.

Profile Cutting Methods:

- Flame Cutting:Uses a high-temperature flame to melt and cut the steel.It's suitable for thicker plates but can produce a rougher cut surfaceaccording to Alloy Carbon Steel.

- Plasma Cutting:Employs a plasma torch to melt and cut the steel.It offers faster cutting speeds compared to flame cutting.

- Laser Cutting:Uses a focused laser beam to cut the steel.It provides high precision and clean cuts, making it suitable for complex shapes.

-

C45 Plate

-

C45 Steel Plate

-

C45 Carbon Steel Plate

-

EN8 / C45 Plate

-

C45 Grade Steel Plate

-

C45 Hot Rolled Plate

-

C45 Steel Sheet

-

C45 Plate Suppliers in Vadodara

-

C45 Plate Manufacturers in Gujrat

-

C45 Plate Exporters

-

C45 Plate Stockists in Gujrat

-

C45 Plate Price per Kg

-

C45 Plate Sizes and Thickness

-

Custom Cut C45 Plate

-

C45 Plate with Mill Test Certificate (MTC)

- C45 plastic mould steel

- Plastic mould steel plate

- C45 mould plate

- Hot rolled C45 plate

- Precision ground C45 plate

- Pre-machined C45 steel

- Dealers of C45 Plate, Circle, Flat bars, Rectangular Plate, Sheets.

-

The top 10 C45 Plate manufacturers are

-

The top 10 C45 Plate Suppliers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plates Category

C45 Carbon Steel Plate For Plastic Mould Industry

Price 80 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Mild Steel

Application : Industrial Unit

Steel Type : Carbon Steel

Product Name : Other

Carbon Steel Plates

Price 90 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : A36

Application : Construction

Steel Type : Carbon Steel

Product Name : Other

MS Heavy Duty Plate

Price 85 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Mild Steel

Application : Construction

Steel Type : Mild Steel

Product Name : Other

Mild Steel Plate

Price 75.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : IS2062 Grade

Application : Construction

Steel Type : Mild Steel

Product Name : Other

Send Inquiry

Send Inquiry Send SMS

Send SMS