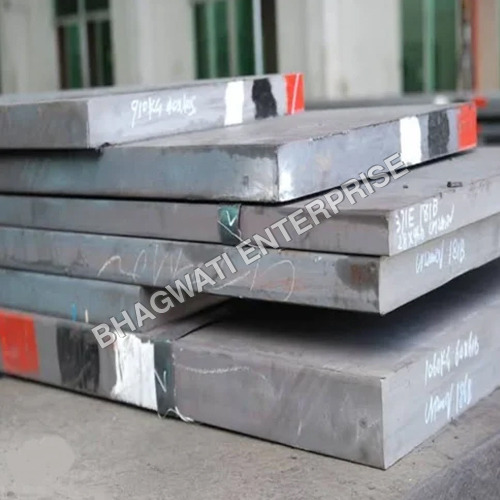

Carbon Steel Plates

Carbon Steel Plates Specification

- Product Name

- Other

- Steel Type

- Carbon Steel

- Grade

- A36

- Shape

- Plate

- Surface

- Polished

- Application

- Construction

Carbon Steel Plates Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 1 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Loose

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Mill T.C.

About Carbon Steel Plates

Carbon steel plate isa versatile and widely used flat sheet of steel primarily composed of iron and carbon, with smaller amounts of other elements like manganese, silicon, sulfur, and phosphorus, and is known for its strength, durability, and ability to withstand high temperatures and pressures, making it suitable for various industrial applications, especially in construction and manufacturing.

Based on carbon content, carbon steel plates are generally categorized into three main types:

- Low Carbon Steel Plate (Mild Steel):Contains less than 0.25% carbon. It is the most common and cheapest type, known for its high ductility, easy weldability, and formability.

- Medium Carbon Steel Plate:Contains 0.25% to 0.60% carbon. It provides a balance of strength, hardness, and ductility, making it suitable for applications requiring both durability and workability.

- High Carbon Steel Plate (Carbon Tool Steel):Contains over 0.60% carbon. This type offers the greatest strength and hardness but is less ductile and more challenging to machine and weld.

-

Carbon Steel Plate

-

Mild Steel Plate

-

Hot Rolled Carbon Steel Plate

-

Cold Rolled Carbon Steel Plate

-

Structural Steel Plate

-

Medium Carbon Steel Plate

-

Low Carbon Steel Plate

-

High Carbon Steel Plate

-

ASTM A36 Steel Plate

-

ASTM A516 Grade 70 Plate

-

EN 10025 S275 / S355 Steel Plate

-

Carbon Steel Sheet Plate

-

Heavy Steel Plate

-

Carbon Steel Plate Supplier in Vadodara

-

Carbon Steel Plate Manufacturer

-

Carbon Steel Plate Exporter

-

Industrial Steel Plate Distributor

-

Bulk Steel Plate Orders

-

Carbon Steel Plate for Export

-

Steel Plate Price per Ton

-

Wholesale Carbon Steel Plate

-

Ready Stock Steel Plate

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plates Category

C45 Carbon Steel Plate For Plastic Mould Industry

Price 80 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Mild Steel

Surface : Coated

Shape : Plate

Steel Type : Carbon Steel

C45 Carbon Steel Plates

Price 85 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : C45

Surface : Coated

Shape : Plate

Steel Type : Alloy Steel

Mild Steel Plate

Price 75.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : IS2062 Grade

Surface : Polished

Shape : Plate

Steel Type : Mild Steel

MS Heavy Duty Plate

Price 85 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Mild Steel

Surface : Coated

Shape : Plate

Steel Type : Mild Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS